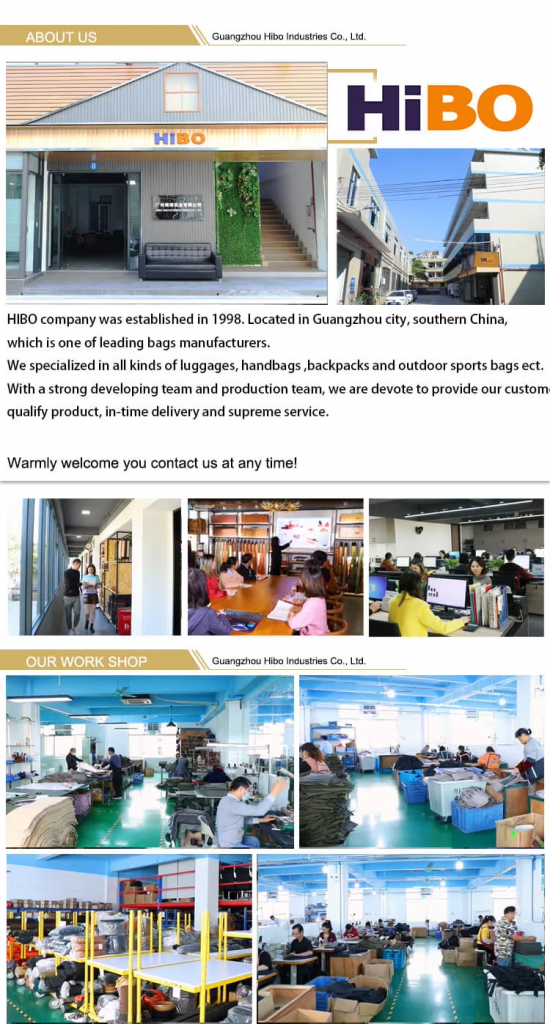

Our Location

No.12, LianBian LianXing First Road, Helong Street, Baiyun Dist., Guangzhou, China, 510440

For leather enthusiasts, the making of Saffiano leather—with its signature crosshatch texture—is a fascinating process. Here’s a breakdown of the four key steps:

The raw hide undergoes tanning to become durable leather. While Saffiano is typically left undyed, some brands infuse color directly into the hide, enhancing contrast under its translucent finish.

Before embossing, the leather is heated to around 70°C, softening the fibers to ensure a crisp, lasting impression.

A high-pressure machine stamps the crosshatch pattern into the warm leather in just 15 seconds. Like a coin die, the metal plate bears an inverted texture to create the final design.

Once cooled, a protective wax coating is applied, delivering Saffiano’s signature gloss and scratch resistance. Some variations include layered finishes—like a subtle two-tone effect—where a secondary color highlights the embossed peaks.

The result? A sleek, durable leather that ages beautifully while resisting wear.

High-Quality New and Customized Leather Goods Are Here!

If you’re looking for a new leather good from one of the industry’s top manufacturers, you’re in the right place.

Many of our leather goods are for customization. Take a look through our online collection and get in touch with us through the INQUIRY if you have any question!

Leather goods like HIBO bags equip modern advanced bag system to help minimize the weight when you are on the road ,having plenty of storage space in the form of specialized pockets for having small things organized, using high-quality material.